GCW-40ST Checkweigher

Static, precise and modular

The GCW-40ST is a static checkweigher that delivers high precision, flexibility and reliability for industrial lines requiring total process control. Its modular design allows the integration of rejection systems, product guides or ramps, while its connection to Giscale Pro software and ERP/MES systems enables real-time data export and traceability.

|

High-precision static weighing |

|

Modular and adaptable design |

|

Integrated GI410 indicator |

|

Connectivity and data traceability |

GCW-40ST Technical Data Sheet

Download the full technical data sheet of the GCW-40ST a static, precise and modular checkweigher designed for demanding industrial environments. Find all the technical specifications, configuration options, Ethernet/RS232 connectivity details, and compatibility with Giscale Pro software.

| Specifications | |

| Weighing type | Static (control or scanner mode) |

| Capacity | 1.5 kg to 30 kg (depending on model) |

| Accuracy | From 0.5 g to 10 g |

| Maximum throughput | Up to 20 ppm |

| Power supply | 230 V AC | 50 Hz |

| Rated power | 400 W |

| Operating temperature | 0 °C – 40 °C |

| Protection rating | IP65 |

| Certification | MID 2014/32/EU (optional “℮” content control 76/211/EEC) |

| Transport system and structure | |

| Weighing platform size (L × W) | 300×200 / 400×280 / 400×400 / 600×400 mm |

| Working height | 800 – 950 mm (adjustable) |

| Transport direction | Right-to-left or vice versa (as specified) |

| Conveyor belts | FDA standard, high-grip or sliding type (depending on application) |

| Load cell type | High-resolution IP67 load cells |

| Frame | AISI 304L stainless steel / anodized aluminum |

| Guides | Stainless steel, anodized aluminum or APM (optional) |

| Interface, software and connectivity | |

| Indicator | Integrated GI410 indicator with LCD display and numeric keypad |

| PC software | Optional Giscale Pro: ERP/MES integration, multi-viewer, traceability |

| Data export | Excel or CSV (grouped by batch or product) |

| Communication | Ethernet | RS232 |

| Customization and options | |

| Light/acoustic beacon | Two colors — visual and audible status control |

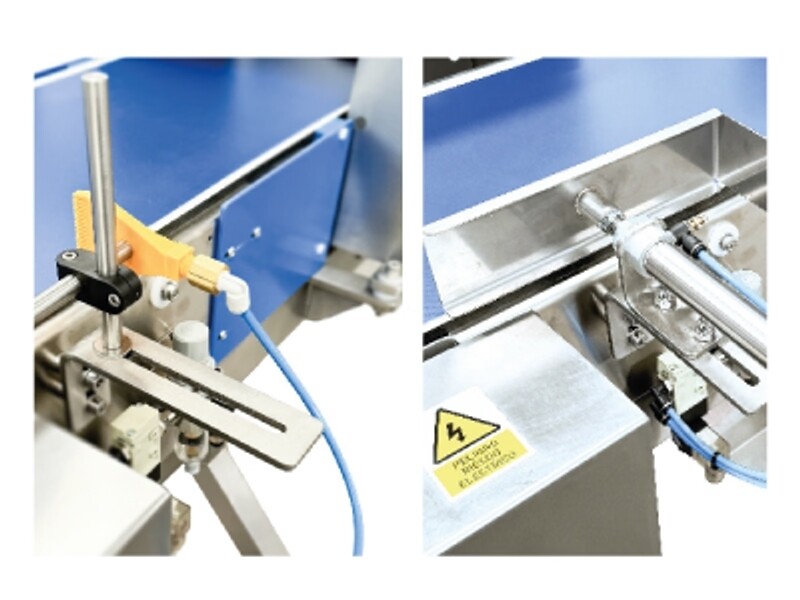

| Additional sensors | Barrier or gantry detector |

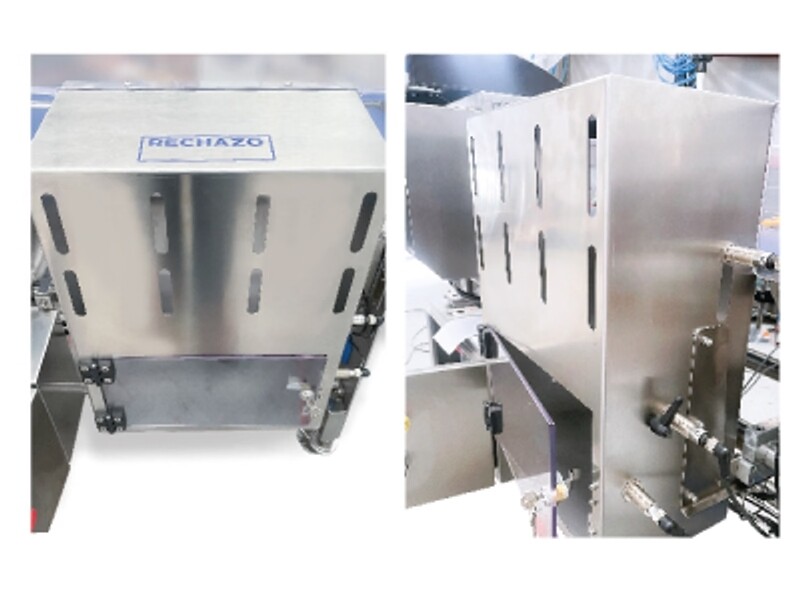

| Rejection systems | Air-jet, pusher or flap system (requires output conveyor) |

| Guides and ramps | APM or stainless-steel guides, ramps and polycarbonate protections |

| Giscale software and modules | Giscale Pro, statistics, real-time production panel, “℮” control module |

Customize your GCW-40ST to fit your production lineConfigure your checkweigher with optional modules that enhance efficiency, safety and traceability. Stay connected to Industry 4.0 by adapting each system to your workflow.

|

GLM-0100

The GLM-0100 is a compact and versatile label applicator designed for cylindrical or square containers. It applies labels or tags on the side or top with high precision and speed. Featuring an adjustable head, modular structure, and high throughput of up to 70 units per minute, it’s the ideal solution to optimize uninterrupted production.

GLM-1000

The GLM-1000 label applicator delivers fast, precise labeling for cylindrical containers from Ø25 to 100 mm. Featuring an adjustable head, integrated conveyor, and multiple options such as special container supports and horseshoe sensors, it ensures versatility and efficiency in demanding production lines.

GLM-3000

The GLM-3000 automatic label applicator is designed for cylindrical containers, featuring up to three labeling heads for maximum flexibility. It offers high precision and speeds of up to 100 containers per minute, ideal for demanding production lines. Customizable with sensors, coders, and additional conveyors.

GLM-2000

The GLM-2000 automatic label applicator is designed for flat, square, and cylindrical containers. It delivers fast and accurate labeling on one or two sides, handling up to 100 units per minute. Flexible, customizable, and easy to integrate into demanding production lines.